Diaphragm pumps have become essential in various industries due to their ability to handle a wide range of fluids, from thick liquids to those with solid particles. Their versatility, reliability, and efficiency make them a preferred choice for fluid transfer in both industrial and delicate processes. Industries rely on diaphragm pumps for their precision, safety, and ability to operate in demanding conditions.

Let’s explore how different industries benefit from this technology.

What Are Diaphragm Pumps?

Diaphragm pumps are a type of pump that moves liquids by pushing a diaphragm back and forth. This movement allows liquids to flow in and out of the pump. One of the best things about diaphragm pumps is their ability to handle a wide range of liquids, from thick and sticky substances to those with solid particles in them. They are often powered by air or mechanical force, making them highly versatile.

But how exactly do these pumps help specific industries?

1. Chemical Processing

In the chemical industry, handling dangerous or corrosive liquids is a major concern. Diaphragm pumps are especially useful here because they can transfer these harsh chemicals without leaking. Made from materials that resist corrosion, they ensure that even the most harmful liquids don’t damage the diaphragm pump.

Chemical processing also requires precise control over how much liquid is moved during production. Diaphragm pumps from providers like KNF offer this accuracy, which helps reduce waste and improves safety. When dealing with risky chemicals, reliability and precision are key, and diaphragm pumps provide both.

2. Food and Beverage Industry

In food and beverage manufacturing, maintaining cleanliness and avoiding contamination is critical. Diaphragm pumps play an important role in this industry because they can handle food products safely. These pumps can move thick liquids like sauces or syrups without damaging them.

Another great benefit is that diaphragm pumps are easy to clean. They can be taken apart quickly for cleaning and sterilizing, which is important for keeping the production process running smoothly. For companies that prioritize hygiene and food safety, diaphragm pumps are a must-have.

3. Pharmaceutical Industry

In the pharmaceutical world, accuracy and cleanliness are essential. Diaphragm pumps are commonly used to transfer delicate substances without risking contamination. They provide a consistent flow of materials, ensuring that every batch of medicine is produced with the same level of care.

Many diaphragm pumps are designed to meet strict hygiene standards, making them perfect for pharmaceutical use. Their ability to handle clean-in-place processes, where equipment is cleaned without being disassembled, also adds to their convenience in medicine production.

4. Water Treatment and Waste Management

Water treatment plants face the challenge of dealing with large amounts of liquid mixed with solid waste. Diaphragm pumps are well-suited for this task because they can handle thick liquids, sludge, and even small solid particles without clogging.

These pumps are known for their durability, which makes them a cost-effective choice for facilities that deal with wastewater. Since they don’t require constant maintenance, diaphragm pumps reduce downtime and ensure the smooth operation of water treatment plants.

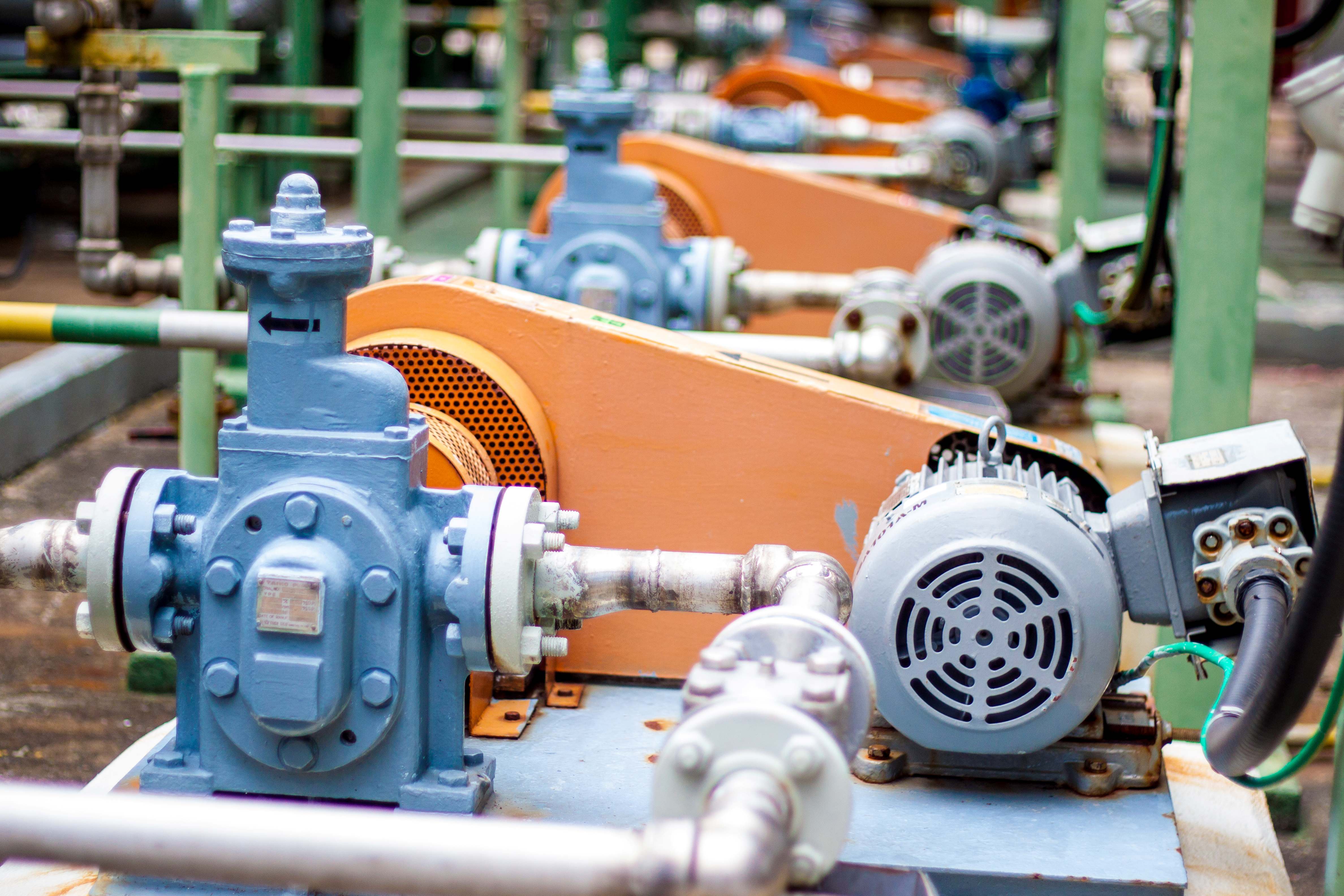

5. Oil and Gas Industry

In the oil and gas industry, handling thick liquids like crude oil requires sturdy equipment. Diaphragm pumps can transfer these heavy, viscous substances without losing efficiency. They can also withstand extreme conditions, making them ideal for this demanding sector.

Safety is another big concern in oil and gas. Diaphragm pumps, which are often air-powered, reduce the risk of electrical sparks, a serious hazard in environments where flammable substances are present. This makes them the safest option for transferring oil and other similar products.

6. Mining and Construction

In mining and construction, heavy-duty equipment is always in demand. Diaphragm pumps are used to remove water, mud, and other materials from work sites. They are strong enough to handle thick, abrasive materials, making them perfect for these tough jobs.

These pumps are also portable, allowing workers to move them easily around construction sites. Their ability to operate under harsh conditions ensures that they are up to the task, no matter how challenging the environment may be.

Why Diaphragm Pumps Are the Preferred Choice

Diaphragm pumps are popular across many industries because they offer a reliable solution for moving liquids safely and efficiently. One major reason is their ability to work without electricity, which is crucial in industries like oil and gas, where safety is a concern. These pumps reduce the risk of sparks, making them a safer option in explosive environments.

Another reason diaphragm pumps stand out is their low maintenance needs. With fewer moving parts compared to other types of pumps, they require less upkeep, which saves both time and money. Plus, they can handle a wide range of liquids, from delicate pharmaceutical compounds to thick sludges, proving their versatility across industries.

Conclusion

Diaphragm pump technology has become an essential tool in industries like chemical processing, food production, water treatment, and mining. Its ability to handle a variety of liquids, maintain high safety standards, and operate in tough environments makes it a top choice for many businesses. As industries continue to grow and face new challenges, diaphragm pumps will remain a key part of